Get Support

07496822205

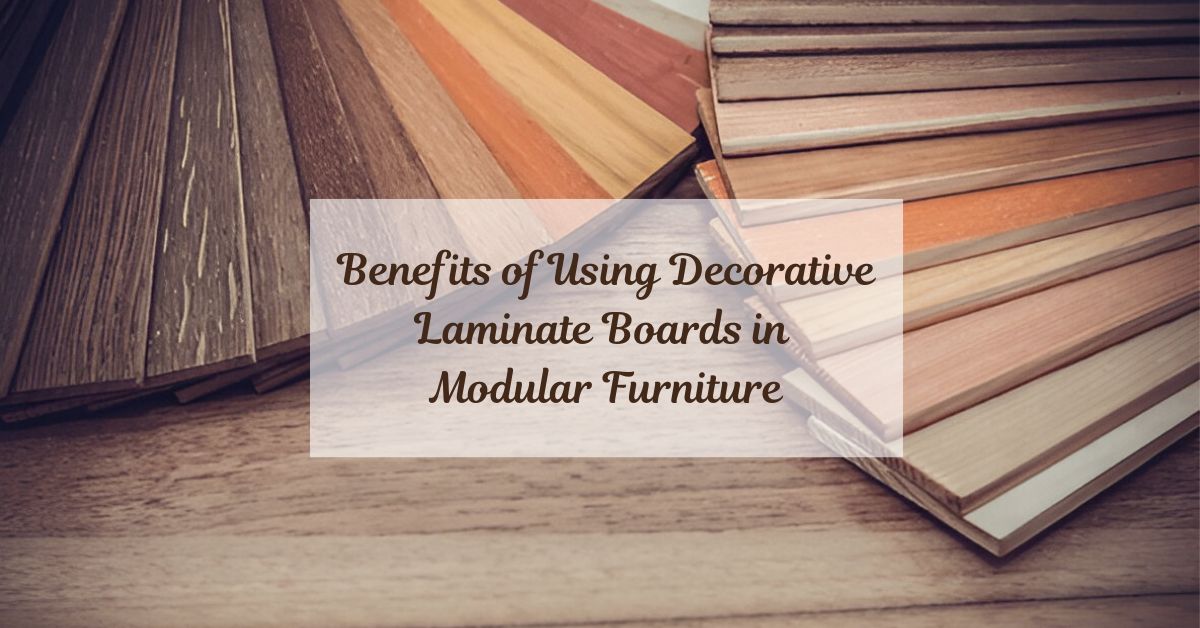

Benefits of Using Decorative Laminate Boards in Modular Furniture

Decorative laminate boards have transformed modular furniture design, providing unrivaled durability, aesthetic flexibility, and cost-efficiency. These engineered surfaces, made by decorative laminate board manufacturers in India and throughout the world, combine numerous layers of resin-infused paper under high pressure to create scratch-resistant, moisture-proof, and visually appealing finishes.

The increased demand for modular kitchens and office furniture has fueled innovation among decorative laminate board manufacturers, who now offer solutions that balance sustainability with high-performance features such as UV resistance and thermal stability. With India growing as a quality production hub, these boards allow designers to reproduce luxury materials like wood and stone at a lower cost while matching a wide range of consumer preferences.

Understanding the Manufacturing Process of Decorative Laminate Boards

The precise production process plays a significant role in the quality and performance of decorative laminate boards. Decorative laminate board manufacturers use a multi-step process to assure durability and aesthetic appeal. The process begins with the careful selection of raw materials and goes through numerous important phases to produce the finished product.

Step One: Impregnation of Kraft Paper

In order to make the Kraft paper rigid and brittle, this paper is saturated with phenolic resin. This impregnation is crucial because it gives the laminate the required strength and durability.

Step two: Drying

The resin-impregnated paper is dried using hot air, swiftly curing the resin and preparing the sheets for further processing.

Step Three: Layering and Stacking

The core is made of dried kraft paper that has been coated with a decorative printed layer and transparent tissue paper impregnated with melamine resin. These layers are properly stacked, with textured plates put between the sheets, not simply to prevent adhering, but also to imprint surface textures as necessary.

Step 4: Thermosetting

Hydraulic presses apply extreme heat and pressure to the piled layers. This thermosetting technique melts the resins, combining the layers to form a single, robust, and long-lasting sheet. If a textured finish is required, pressing imprints texture onto the surface.

Step 5: Finishing

Following pressing, the laminate sheets are trimmed to size, sanded on the backside to guarantee appropriate adherence during furniture manufacture, evaluated for quality, and packaged for shipment.

This comprehensive manufacturing process assures that decorative laminate boards provide consistent quality, strength, and visual appeal, making them perfect for modular furniture applications.

Conclusion

Incorporating decorative laminate boards into modular furniture has various advantages, ranging from increased durability and aesthetics to ease of maintenance and personalization. These boards not only improve the cosmetic attractiveness of furniture, but they also provide long-term performance in both household and business environments.

With the rising demand for beautiful and functional interiors, selecting the correct materials is critical. Reputable decorative laminate board manufacturers in India offer a wide choice of high-quality solutions to meet a variety of design requirements, providing both style and substance in each modular furniture project.

By: Ethan

By: Ethan